Maglite ML25LT Disassembly: A Step-by-Step Guide

The Maglite ML25LT is a popular LED flashlight known for its durability, versatility, and impressive performance. Crafted from high-strength aluminum alloy, the ML25LT is designed to withstand tough conditions, making it a reliable companion for outdoor enthusiasts and professionals alike.

This flashlight boasts features such as a remarkable beam throw of 337 meters and a runtime of up to 72 hours in low mode, providing exceptional illumination when needed. However, like any device, it may require disassembly for maintenance or repairs, whether to replace faulty components or simply to clean and refresh its internal parts.

This comprehensive guide aims to equip you with the knowledge and confidence to tackle the disassembly of the Maglite ML25LT. It will detail the necessary tools, the step-by-step procedure for disassembly, and highlight common issues that may arise during the process.

By following this guide, you can ensure your flashlight remains in optimal condition, helping you to make the most of its impressive capabilities.

Table of Contents

- Tools Needed for Disassembly

- Preparing the Maglite ML25LT for Disassembly

- Disassembling the Head of the Flashlight

- Removing the Switch Assembly

- Cleaning and Maintenance

- Replacing Damaged Parts

- Reassembling the Maglite ML25LT

- Common Issues and Solutions Post-Disassembly

- Upgrading the Maglite ML25LT

- FAQ

- Conclusion

Tools Needed for Disassembly

Before embarking on the disassembly process of your Maglite ML25LT, it is crucial to gather the appropriate tools. This preparation ensures a smooth and efficient disassembly experience.

In this section, we will outline the necessary tools and provide safety precautions to keep in mind.

Recommended Tools

- Flathead Screwdriver: Useful for prying open components and removing screws.

- Phillips Screwdriver: Required for screws that secure various parts of the flashlight.

- Soft Mallet: Helpful for gently tapping components to free them without causing damage.

- Cotton Swabs and Alcohol: Essential for cleaning the internal parts post-disassembly.

- Lubricant (Silicone Grease): Used to maintain the O-rings and ensure smooth reassembly.

Safety Precautions

When working with electrical devices, safety should be your top priority. Always ensure the flashlight is turned off and remove the batteries before beginning any disassembly.

Additionally, wear protective eyewear to guard against any debris that may dislodge during the process.

| Tool | Description | Use |

|---|---|---|

| Flathead Screwdriver | A tool with a flat blade to turn screws | Prying open components |

| Phillips Screwdriver | A tool with a cross-shaped tip | Removing screws |

| Soft Mallet | A mallet made of soft materials | Gentle tapping on components |

| Cotton Swabs | Small sticks with cotton ends | Cleansing internal parts |

| Lubricant | A silicone-based grease | Maintaining O-rings |

The table above summarizes the essential tools and their uses, highlighting how each tool plays a role in ensuring a successful disassembly of the Maglite ML25LT. The use of appropriate tools not only makes the task easier but also minimizes the risk of damaging components during the process.

Proper maintenance and care will extend the life of your flashlight, allowing it to perform optimally in any situation.

Preparing the Maglite ML25LT for Disassembly

Preparation is key before disassembling your Maglite ML25LT. This involves a few critical steps to ensure that you can safely and effectively work on the flashlight.

This section will guide you through the necessary preparations, including removing the batteries and inspecting for damage.

Removing Batteries

Before starting the disassembly, the first step is to remove the batteries from the flashlight. This step is crucial to avoid any electrical shocks or short circuits during the disassembly process.

Simply unscrew the tail cap of the flashlight and take out the batteries. If you encounter any stuck batteries, gently tap the flashlight against a soft surface to help them dislodge.

Inspecting for Damage

Once the batteries are removed, it is essential to inspect the flashlight for any signs of damage. Look for corrosion around the battery contacts, which can occur if batteries are left in for an extended period.

Corrosion can hinder performance and cause electrical issues. Additionally, check for any physical damage to the body or the lens of the flashlight.

| Inspection Aspect | Importance | How to Check |

|---|---|---|

| Battery Contacts | Corrosion can prevent the flashlight from functioning | Look for any white or green residue |

| Body Integrity | Physical damage can affect performance | Check for dents, scratches, or cracks |

| Lens Condition | Damaged lens can diminish light output | Look for scratches or cracks |

The table above illustrates the key aspects to inspect before disassembly. By paying attention to battery contacts, the integrity of the body, and the condition of the lens, you can identify any issues that may need addressing during the disassembly process.

Regular inspections and maintenance can significantly prolong the lifespan and functionality of your Maglite ML25LT, ensuring it is always ready for use.

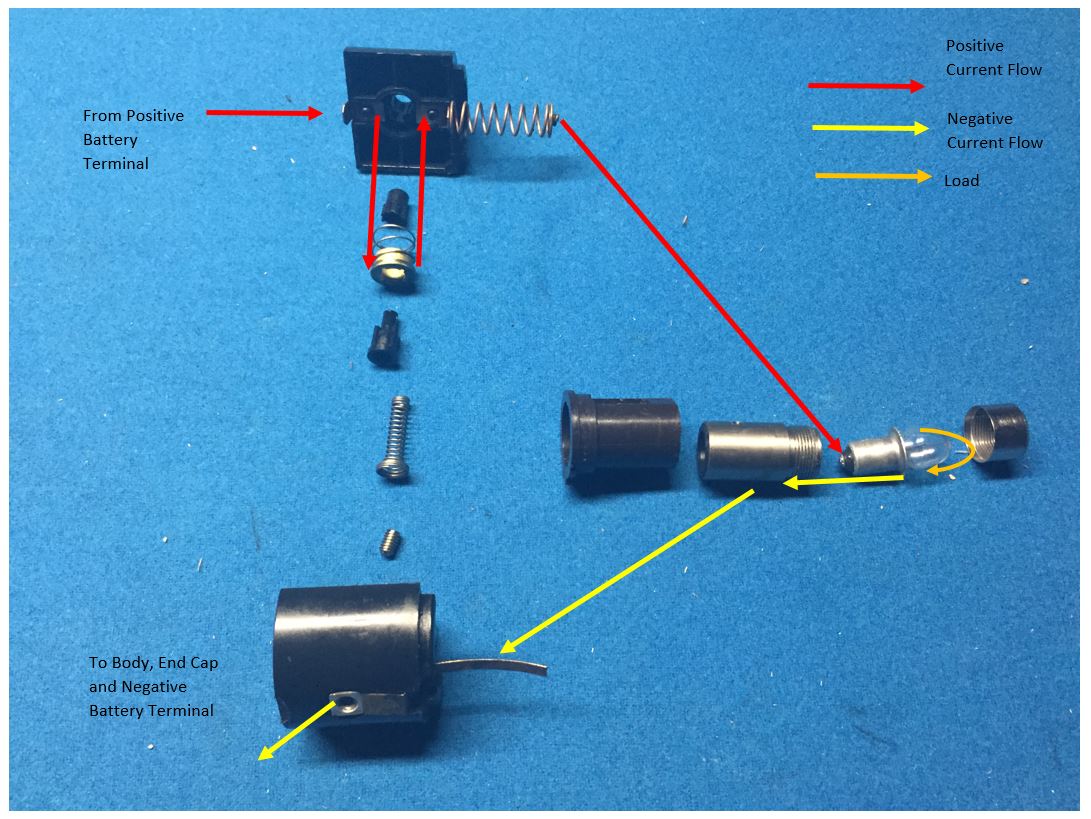

Disassembling the Head of the Flashlight

The next step in the disassembly process involves removing the head of the Maglite ML25LT. This is a crucial part of accessing the internal components and should be done carefully to avoid damaging the flashlight.

This section will detail the procedure for head removal, including the tools required and common issues you might encounter.

Tools Required for Head Removal

To successfully remove the head, you will need a flathead screwdriver and possibly a soft mallet for any stubborn components. The flathead screwdriver can be used to pry the head gently, while the mallet can assist in tapping the head if it is stuck due to corrosion or tight fittings.

Common Issues Encountered

During the disassembly of the head, you may encounter several issues. One common problem is corrosion, which can cause components to stick together.

If you find that the head does not twist off easily, applying a gentle tapping motion with the soft mallet can help dislodge it. Be careful not to use excessive force, as this could damage the threads.

| Issue | Possible Cause | Solution |

|---|---|---|

| Stuck Head | Corrosion from battery leakage | Use a soft mallet to tap gently |

| Damaged Threads | Over-tightening during previous use | Inspect and clean threads carefully |

| Misalignment | Improper reassembly in the past | Realign and ensure proper fit |

The table above outlines common issues you might face while disassembling the head of your Maglite ML25LT. Understanding these issues and their solutions will help you navigate the disassembly process more effectively.

Regular maintenance and careful handling can prevent many of these problems, ensuring that your flashlight remains in excellent condition.

Removing the Switch Assembly

The switch assembly is another critical component of the Maglite ML25LT. If the flashlight is not functioning properly, the switch may be the source of the issue.

This section will explain how to access and remove the switch assembly, as well as troubleshoot common problems associated with it.

Accessing the Switch Assembly

To access the switch assembly, you must first remove the head and then gently pull the body apart at the tailcap. The switch assembly is typically secured with screws that can be removed using a Phillips screwdriver.

Take care to keep track of these screws and any small components that may fall out during the process.

Troubleshooting Switch Issues

If your flashlight does not operate, it may be due to a faulty switch. Inspect the switch assembly for any signs of wear or damage.

If necessary, you can replace the switch with a new assembly. Ensure that the new switch is compatible with your model to avoid further issues.

| Issue | Possible Cause | Solution |

|---|---|---|

| Flashlight Won’t Turn On | Faulty switch assembly | Replace with a new switch assembly |

| Intermittent Power | Loose connections in the switch | Tighten connections and clean contacts |

| Stuck Switch | Debris buildup | Clean the switch area thoroughly |

Cleaning and Maintenance

After disassembling your Maglite ML25LT, it is crucial to clean the components thoroughly to maintain optimal performance. Dirt, debris, and corrosion can accumulate over time, affecting the flashlight’s functionality.

This section will provide cleaning methods for various parts of the flashlight, emphasizing the importance of regular maintenance.

Cleaning the Body and Lens

To clean the body of the flashlight, use a soft cloth and a mild cleaning solution. Avoid harsh chemicals that may damage the aluminum finish.

For the lens, a specialized lens cleaner can be used to remove scratches and improve clarity. Gently buff the lens with a microfiber cloth to restore its shine.

Maintaining the O-rings and Seals

The O-rings are essential for ensuring the water resistance of the flashlight. Regularly inspect and clean these seals, applying a thin layer of silicone grease to keep them flexible and effective.

This maintenance will prevent leaks and prolong the life of your flashlight.

| Component | Cleaning Method | Frequency |

|---|---|---|

| Body | Soft cloth with mild cleaner | Every few months |

| Lens | Lens cleaner and microfiber cloth | As needed |

| O-rings | Inspect and apply silicone grease | Every few months |

The table above outlines the recommended cleaning methods and frequencies for the various components of the Maglite ML25LT. Regular cleaning and maintenance not only enhance the flashlight’s performance but also ensure its longevity.

By taking the time to care for your flashlight, you can enjoy its reliable performance for years to come.

Replacing Damaged Parts

If you discover any damaged components during disassembly, it’s important to replace them to ensure the flashlight operates correctly. This section will guide you through identifying damaged parts and sourcing replacement components.

Identifying Damaged Components

Common components that may need replacement include the switch assembly, LED module, and O-rings. Inspect each part carefully for signs of wear, corrosion, or physical damage.

If a part appears compromised, it’s essential to replace it to maintain the flashlight’s integrity.

Sourcing Replacement Parts

Replacement parts for the Maglite ML25LT can typically be sourced from Maglite retailers or online marketplaces. Ensure that any replacement parts are compatible with your specific model to avoid issues during reassembly.

Prices for common replacement parts can vary, so consider checking multiple sources for the best deal.

| Component | Common Replacement Source | Estimated Cost |

|---|---|---|

| Switch Assembly | Maglite retailers | $5 – $15 |

| LED Module | Maglite or online marketplaces | $10 – $30 |

| O-rings | Maglite retailers | $2 – $5 |

The table above provides an overview of common replacement components for the Maglite ML25LT, including sourcing options and estimated costs. Being aware of these details can help you plan for repairs and maintenance, ensuring your flashlight remains functional and reliable.

Reassembling the Maglite ML25LT

After performing maintenance or replacing any damaged parts, the next step is to reassemble the Maglite ML25LT. Proper reassembly is critical to ensure all components fit securely and the flashlight functions correctly.

This section will provide detailed instructions for reassembly and tips for testing the flashlight afterward.

Step-by-Step Reassembly

Begin reassembly by reversing the disassembly steps. Ensure that all components are clean and lubricated where necessary.

Carefully align the switch assembly back into the body, ensuring it fits snugly. Next, attach the head and tailcap, twisting them securely in place.

Take care to avoid cross-threading any components.

Testing the Flashlight

Once reassembly is complete, it’s important to test the flashlight to ensure it operates correctly. Insert fresh batteries and turn the flashlight on.

Check the beam for brightness and focus. If issues arise, revisit your assembly steps to ensure everything is properly secured.

| Step | Action | Tip |

|---|---|---|

| 1 | Align the switch assembly | Ensure tight fit |

| 2 | Attach the head of the flashlight | Avoid cross-threading |

| 3 | Secure the tailcap | Twist firmly in place |

| 4 | Insert new batteries | Check for proper orientation |

| 5 | Test the flashlight | Observe beam quality |

The table above summarizes the essential steps for reassembling the Maglite ML25LT flashlight. Following these steps carefully will help ensure that your flashlight functions properly after maintenance.

Proper reassembly is critical not only for performance but also for safety, as loose components could lead to malfunctions.

Common Issues and Solutions Post-Disassembly

After reassembling the Maglite ML25LT, you may encounter some common issues. This section will address potential problems that can arise and provide solutions to help you troubleshoot effectively.

Troubleshooting Common Problems

If the flashlight does not turn on after reassembly, the issue may lie in the battery contacts or the switch assembly. Inspect these areas for corrosion or loose connections.

If the flashlight flickers, it may indicate a loose connection within the switch assembly. Tighten any screws and ensure all components are securely in place.

When to Seek Professional Help

In cases where the flashlight still does not function properly after troubleshooting, it may be time to seek professional help. If you encounter severe corrosion, damaged components, or if the flashlight has extensive wear, professional servicing may be necessary to restore it to proper working condition.

| Issue | Potential Cause | Solution |

|---|---|---|

| Flashlight Won’t Turn On | Corroded contacts | Clean and replace contacts |

| Flickering Beam | Loose connection | Tighten switch assembly screws |

| Beam Quality Poor | Dirty lens | Clean lens with microfiber cloth |

The table above highlights common issues you may face post-disassembly and their corresponding solutions. Understanding these problems will allow you to troubleshoot effectively and maintain the functionality of your Maglite ML25LT.

If issues persist, do not hesitate to reach out for professional assistance to ensure your flashlight is restored to peak performance.

Upgrading the Maglite ML25LT

For users looking to enhance their flashlight’s performance, upgrading certain components can significantly improve functionality. This section will discuss potential upgrades, including LED modules and battery types, along with their benefits.

Benefits of Upgrading

Upgrading to a more efficient LED module can greatly enhance the brightness and efficiency of your Maglite ML25LT. High-quality LED modules can provide brighter light output with lower power consumption, extending battery life.

Additionally, using high-capacity rechargeable batteries can reduce long-term costs while providing consistent performance.

Recommended Upgrades

Some recommended upgrades include installing a Malkoff LED module, which offers improved brightness and beam quality. Replacing standard batteries with high-capacity NiMH or lithium-ion batteries can also enhance performance and runtime.

These upgrades can transform your traditional flashlight into a modern, high-performance tool.

| Upgrade Type | Description | Benefits |

|---|---|---|

| LED Module | High-efficiency replacement module | Increased brightness, improved efficiency |

| High-Capacity Batteries | NiMH or lithium-ion batteries | Extended runtime and reduced costs |

| Reflector Replacement | Upgraded reflector for better beam quality | Enhanced focus and light distribution |

The table above outlines potential upgrades for your Maglite ML25LT, highlighting their benefits and improvements in flashlight performance. Upgrading not only enhances the functionality of your flashlight but also ensures it remains competitive with newer models on the market.

FAQ

What tools do I need to disassemble the Maglite ML25LT?

To disassemble the Maglite ML25LT, you’ll need a flathead screwdriver, a Phillips screwdriver, a soft mallet, cotton swabs, and silicone grease. These tools will help you safely open the flashlight, clean components, and ensure everything is properly lubricated during reassembly.

How do I clean the internal parts of my flashlight?

Cleaning the internal parts involves removing the head and tailcap, then using cotton swabs and alcohol to remove any dirt or corrosion. Ensure the components are dry before reassembling, and lubricate the O-rings with silicone grease to maintain their flexibility.

Can I replace the LED module in my Maglite ML25LT?

Yes, you can replace the LED module in your Maglite ML25LT with a compatible high-efficiency LED module. This upgrade can significantly enhance brightness and efficiency while extending battery life, making it a worthwhile investment for improved performance.

What should I do if I encounter a stuck battery?

If you encounter a stuck battery, try tapping the flashlight gently against a soft surface to dislodge it. If that doesn’t work, you can soak the flashlight in warm, soapy water to dissolve any corrosion before attempting to remove the battery again.

How often should I perform maintenance on my flashlight?

It is advisable to perform maintenance on your flashlight every few months or after extensive use. Regular inspections and cleanings can prevent corrosion and ensure optimal performance, extending the overall lifespan of your Maglite ML25LT.

Conclusion

In conclusion, disassembling the Maglite ML25LT is a manageable task with the right tools and guidance. By following the steps outlined in this article, users can ensure their flashlight remains in top condition, providing reliable performance when needed most.

Regular maintenance not only extends the life of the flashlight but also enhances its functionality, making it an indispensable tool for various situations. Whether for personal use or professional demands, keeping your Maglite ML25LT in optimal condition is essential.